Premium Faux fur plush fabrics

Professional manufacturer of knitted plush fabrics faux fur with pile heights from 1mm to 40mm

Specialty Textile Innovation Since 2015

GM TEXTILE specializes in faux fur plush fabric manufacturing with state-of-the-art production facilities

Square Meters Facility

Knitting Machines

Tons Daily Production

mm Pile Height Range

Our Featured Product Range

Various collection of knitted plush fabrics faux fur for diverse applications

-1.jpg)

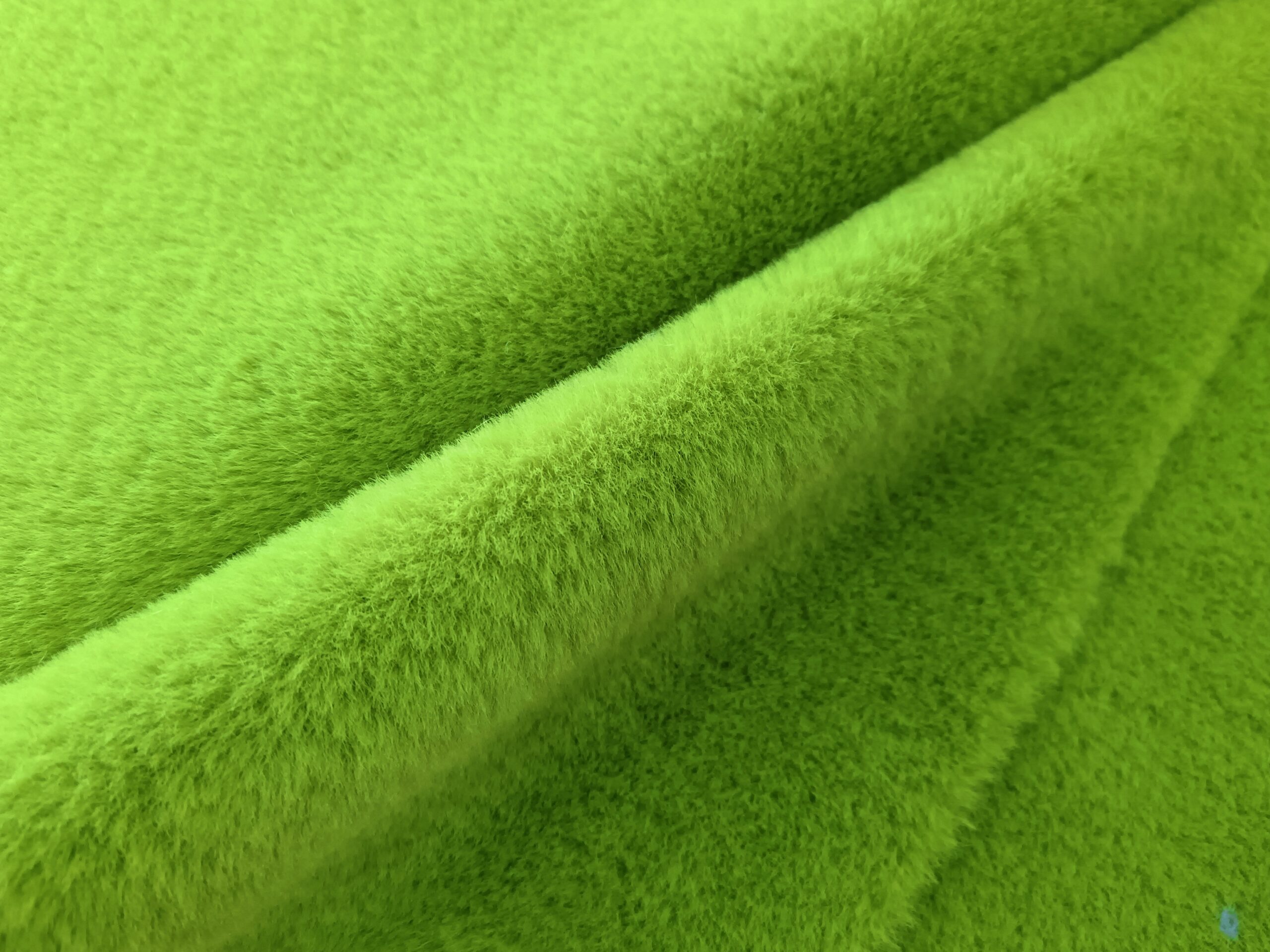

Long Pile Fabrics

Luxurious high pile fabrics with exceptional softness and comfort for premium applications

Learn More →

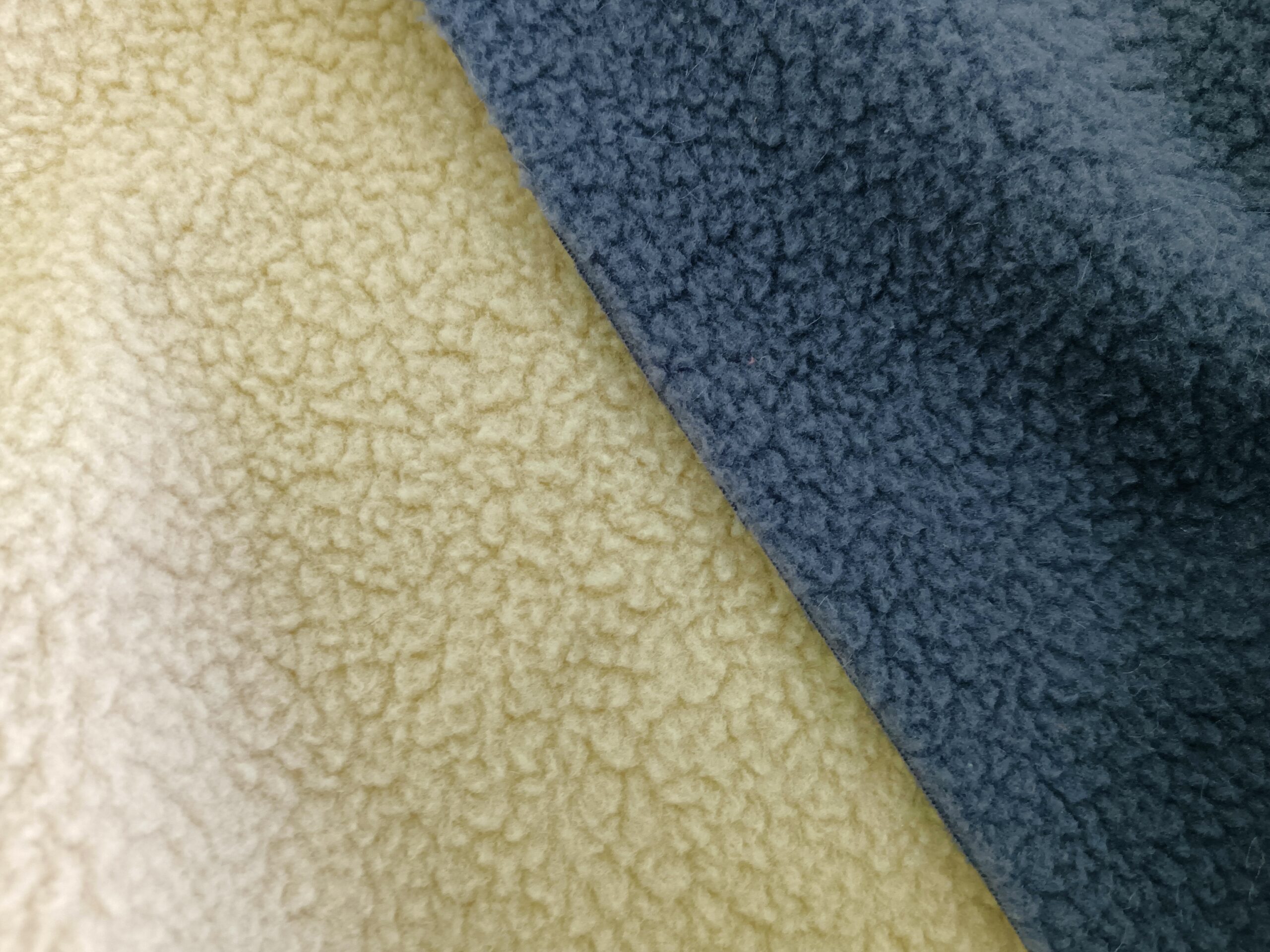

Bonded plush fabric

High-performance laminated fabrics with superior durability and protective coating

Learn More →

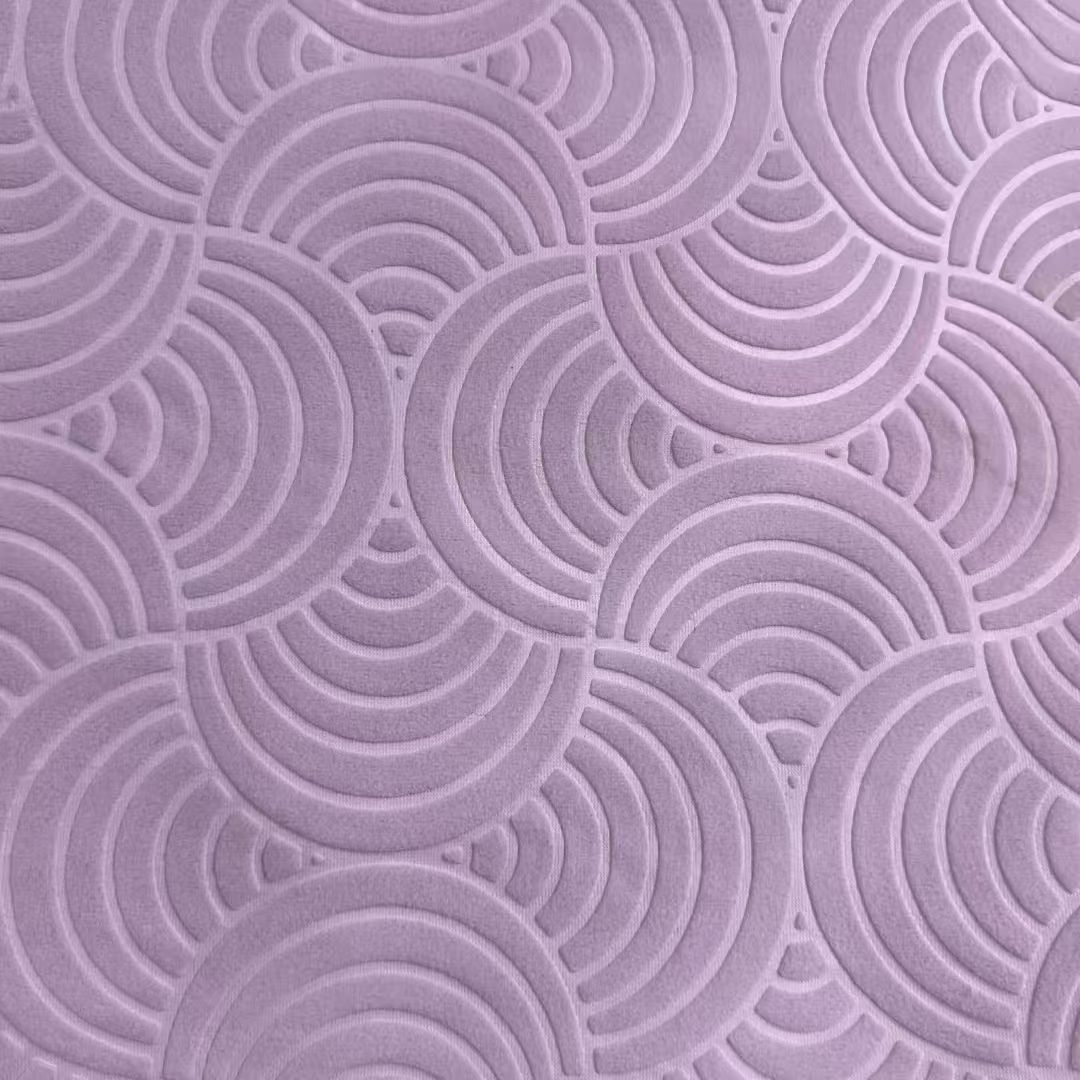

Embossed & Carved

Sophisticated embossed and carved fabrics with distinctive raised patterns

Learn More →

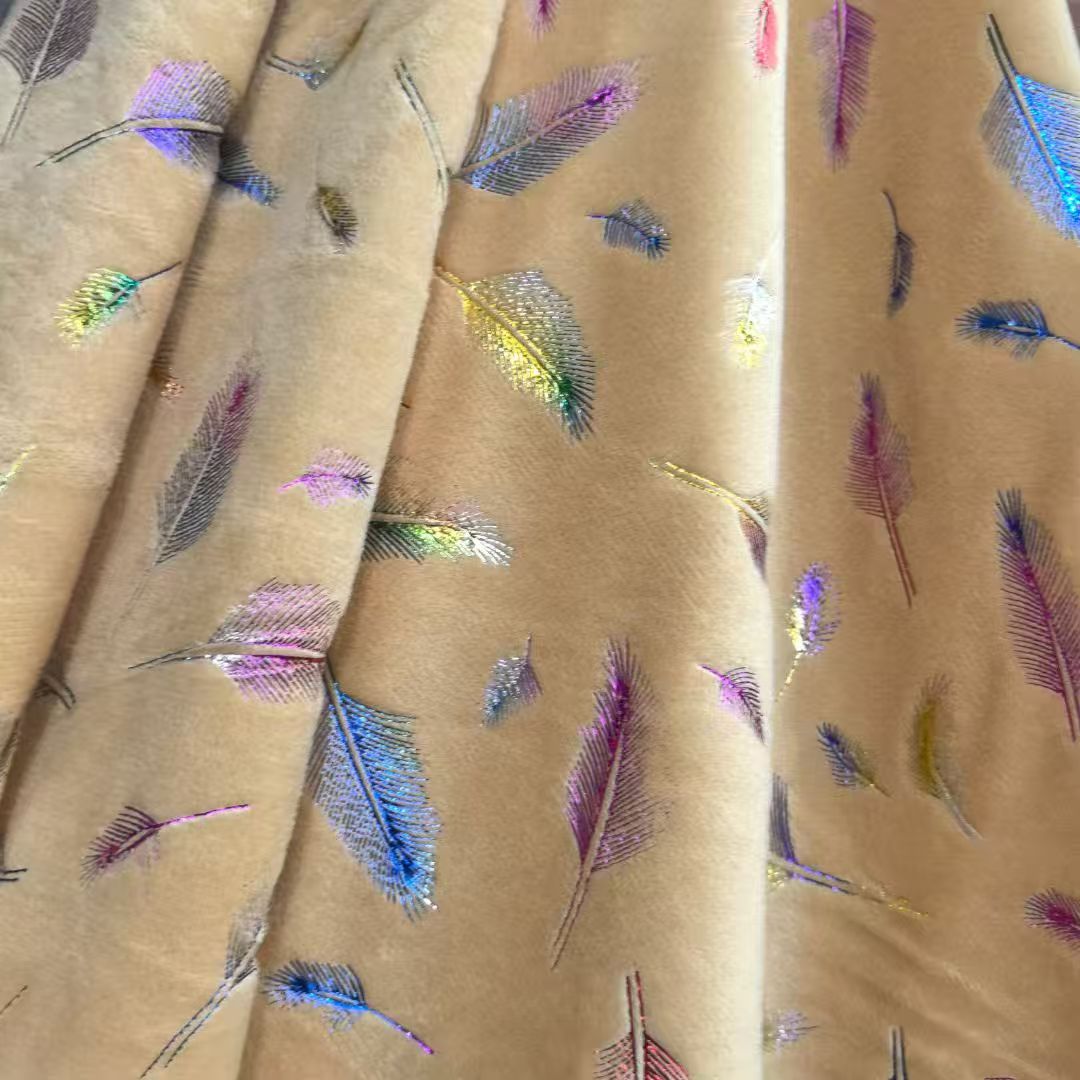

Foil Printed

Premium foil printed fabrics with metallic accents and stunning visual effects

Learn More →Wide Range of Applications

Our fabrics serve diverse industries with specialized solutions

Apparel

Clothing & Fashion

Accessories

Shoes & Bags

Toys

Plush Toys

Home Textiles

Blankets & Décor

Carpets

Rugs & Mats

Pet Products

Beds & Accessories